Inprocess Moisture Measurement

Continuous inline moisture measurement of materials like: concrete, food, pellets, grain, beans, rice, nuts, coal, powder, paste, biomass, wood chips, proteins, fly ash, sawdust, ceramics and soil on conveying equipment or in silos.VHF / Microwave Moisture Measurement

All materials have a specific moisture content, which is bound in the material, but at its least materials

contain nuclear residual moisture. PCE Instruments has focussed on the measurement of bound moisture which is

added or expelled during the manufacture of a product, for example in hygroscopic materials in relation to the

moisture of the given environment. Knowledge about the absolute moisture content of materials upon delivery of

raw materials and during the various stages of the production process is of great importance.

Moisture

content measurement of the finished product alone is not sufficient; the product stability which customers

expect results primarily from a product's qualitative characteristics - one of them being its moisture

content. Moisture measurement instruments are always subject to development cycles. In recent years "Inprocess

Moisture Measurement" (moisture measurement during the uninterrupted manufacturing process) has made great

progress in terms of reproducibility and downtime. PCE focuses on two main features for their measurement

instruments:

1.- High accuracy.

2.- Close process orientation

Currently, PCE offers sensors for inprocess moisture measurement with an accuracy of up to 0.2 %. New

instruments which are currently under development will achieve accuracy values that are significantly lower

than previously attainable results. PCE puts emphasis on innovative and new designs and offers specialized,

robust and low-maintenance moisture measurement systems for many different industries. The moisture content is

always precisely measured - be it in containers, silos and tanks, on conveyor belts or in pipes. The data

which is collected by the inprocess moisture measurement instruments can be directly transferred to process

control systems. Direct process interventions are handled through tele-control systems. PCE does not only

offer a measurement instrument but a complete moisture measurement solution for the needs of the manufacturing

industry.

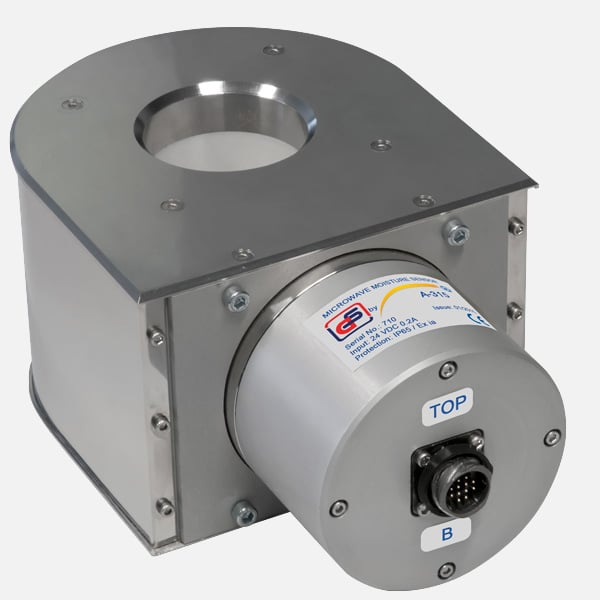

PCE-A-315 Microwave Moisture Measurement Sensor (Grain)

The inprocess microwave grain moisture measurement instruments are developed by Aquar System Ltd. in Minsk and

has been deployed in many grain processing facilities for continuous moisture measurement.

PCE

Instruments offers delivery, modification and on-site installation, calibration and maintenance in Western

Europe, the United States, Canada, and South America. The default calibration curves of this moisture analyzer

allow for continuous and automated measurement of absolute moisture content in goods like grain, legumes and

oil seeds.

Since grain-drying is an energy intensive process, controlling this drying process offers

tremendous cost savings. The online moisture analyzer is particularly well suited for this task when it is

employed during the steaming process and before the milling of grain. The inprocess microwave moisture sensor

makes a fast and accurate measurement possible, especially for materials as rice, wheat,

beans.

Benefits:

- Grain moisture is continuously measured during mass flow (inprocess moisture

measurement) independent of material density and with a high degree of reproducibility.

- Long-term

stability of measurement system; after initial calibration there is no need for scheduled recalibrations. The

microwave moisture analyzer is practically free of natural.

Measurable materials: grain, wheat,

soybeans, rice, salt, wheat chaff, corn rye, triticale, spelled seeds, barley, oats, rape, pumpkin seeds,

peas, beetle beans, horse beans, sunflower seeds, amaranth, flax, sorghum, coffee, cocoa beans, flax seeds,

jatropha, buckwheat, sesame, sorghum, hops, sugar, unpeeled rice, peeled brown rice, poppy seeds, etc.

| Measurement range for moisture content during continuous mass flow | 5 ... 45 % |

| Max. absolute error of moisture measurement | ±0,2 % (rango: 5 ... 15 %) ±0,2 % (rango: 15 ... 18 %) ±1,0 % (rango: 18 ... 45 %) ±5 ... +55 °C |

| Working temperature range | -±5 ... +55 °C |

| Operation mode continous | Continuous operation |

| Measurement period | 0.2 s |

| Power supply | 110 ... 230 V AC |

| Input power | Up to 5 W |

| Warm-up time at start-up | Ca. 60 min |

| Outputs | RS-232, RS-485, 4-20 mA |

| Housing material | Stainless steel |

| Protection class | IP65 / EX ia |

| Weight | Max. 15.5 lbs / 7.0 kg |

Moisture of goods and materials can be accurately measured with the microwave moisture meter. The

material list includes grains like wheat, barley, triticale (animal compound feed from wheat and rye),

rye, oats, maize, millet, buckwheat legumes, lupine seeds, rapeseed, sunflower seeds ( number of

measurable field fruits: 25 different species).

The inprocess microwave moisture measurement is

not only used to measure moisture content during continuous processing but it can also be connected to

evaluation software, data loggers, process controllers and complete process control systems through

various interface options like RS-232, RS 485 or 4-20 mA.

Thus, the inprocess microwave moisture

measurement sensor becomes an integrated part of the complete measurement and process control chain. The

operating principle of the moisture meter is based on the differentials between the ultrahigh frequency,

dielectric characteristics of grains and water. The meter has a ring resonator in its center which has a

dielectric canal through which the grain flows. The parameters of the resonator are changed when the

electromagnetic waves come into contact with the different moisture grades of various grains.

The

fact that the resonator measures two parameters - resonant frequency and resonant amplitude -

simultaneously and its combination with a specialized process control algorithm give the moisture

measurement meter a distinct advantage: independent of material density, a high degree of measurement

reliability and reproducibility is achieved. There is no damage to the tested material or the sensors.

Since the transmission is very low there is no heating or deformation of the tested material.

PCE-MWM 200 VHF-Band Moisture Measurement Sensor (Oil, Sand, Broken Stone)

Probe moisture meter PCE-MWM 200 includes a sand moisture measurement sensor consisting of a central pin-probe

and four-screen pins placed around the central one. Probes and sensor housing are made of stainless steel AISI

321. The probe moisture meter PCE-MWM 200 is designed for installation in tanks with liquid materials such as

fuel oil, slurry from cement production, coal-water fuel (CWF), etc. The moisture measurement sensor housing

and its probes are made of AISI 321 stainless steel. Pin diameter – 12 mm, gap between the central and shield

pins – 25 mm. A large gap between the pins makes the moisture measurement sensor resistant to

clogging.

The top of the sensor is made as a coupling with 1" female pipe thread, which allows mounting

the sensor on a pipe of 33 mm diameter. The cable connecting the sensor and the electronic unit is laid

through this airtight-connected pipe. Such sensor mounting allows adjusting the depth of its immersion in the

tank and monitoring moisture at different levels.

Mounting of the pipe to the moisture measurement

sensor is sealed with silicone sealant.

The use of stainless steel and special dielectric spacers

provides corrosion resistance and allows using the moisture analyzer in pipes with liquids of 145°C

temperature. The range of measured environment temperature can be extended up to 800 °C due to ceramics and

high-temperature alloys application. In the instruments case the accuracy of environment permittivity

measurement remains virtually the same as that of the sensors for temperatures up to 145°C.

Measurable

materials: oil, gasoline, diesel oil emulsion, liquids, sand, broken / crushed stone

| Readings range of the mass fraction of water, W | 0 ... 100 % |

| Moisture measurement range | 0,1 ... 100 % (mass fraction of water) |

| Limits of permissible absolute error of the measurements results of the mass fraction of water | Where W is the measurements result |

| Temperature display range | -50 ... +150 °C |

| Temperature measurement range | -5 ... +80 °C |

| Limits of permissible absolute error of the temperature measurements | ±1 °C |

| Output interface - Digital / - Current | RS 485 Modbus RTU / 4-20 mA |

| Voltage supply - Rated / - Allowable | 24 VDC / 18-36 VDC |

| Consumption current, not more than | 200 mA |

| Overall dimension of the sensors | 335 x 80 x 80 mm |

| Sensor mass, not more | 8 kg |

| Range of working temperatures (sensor operation) -Common industrial execution -With the widened temperature range |

-20 ... +120 °C -20 ... +145 °C |

| Range of working temperatures of the electric sensor unit operations | -20 ... +80 °C |

| Overall dimension of the electric unit | 255 x 170 x 60 mm |

| Electric unit mass | 2 kg |

| Average service life | 10 years |

The electric unit contains a generator that is re-tuned

according to the frequency in VHF band of the wavelengths. Simultaneously wave parameters of the

transmission line are measured. Transmission line is formed by a sensor rod and a metal base (the hopper

wall, pipe wall, etc.) or by two or more rods. In the moment of the resonance achievement the resonance

Q-factor is measured and the frequency of the harmonic signal is stored, that is produced by the

generator. These parameters measured in the controlled material and in the air, allow to calculate the

refraction index of the material (deceleration factor of the electromagnetic wave in the material) and

its dielectric permittivity. According to the conversion tables, drawn up for the temperature set and

saved in the memory of the electronic unit for the selected material, the moisture measurement meter

microcontroller calculates the material moisture. Type of the controlled material (sand, broken stone,

diesel oil emulsion, etc.) is entered into the electronic unit memory from the computer.

For

illustration of the moisture measurement instruments operation principle it should be noted that the

dielectric permittivity of water is approximately 80, the dielectric permittivity of the majority of

dry-out materials is in the range from 2 to 4 (very rarely up to 10 or higher).

Such a

significant difference between the dielectric constant of the water and other materials allows to

determine the water content in the mixture due to the marked increase of the total dielectric

permittivity of the mixture if any moisture is present in the material. Pay attention: dielectric

permittivity of ice is about 3, that is why the moisture meter data (as well as all known industrial

moisture meters of other types) do not allow to measure the amount of ice. The calculated moisture value

/ data is transferred from the electronic unit output through the digital interface (RS-485) and,

simultaneously, as the current signal 4-20 mA to the external indicator or industrial controller which

monitors the technical process.

PCE-MWM 210 VHF-Band Moisture Measurement Sensor Concrete (container / mixer)

Among the range of the materials for the measurement of moisture content in which the moisture meters are used

concrete takes a separate place. It allows conducting the measurement of moisture content inside the

concrete-mixers, to check the quality of the mixture and its consistence. Those materials that have got high

conductivity and permittivity (coke, ore etc) are especially good for being measured with that particular

moisture meter. As in the other versions the moisture measurement model PCE-MWM 210 consists of the electronic

unit and a sensor. In that case the sensor is remote.

Peculiarity of the sensor design (construction)

is the following: its front surface is protected by the plate made of alloy 40X13 – stainless steel with

higher resistance to the abrasive wear-out. The same plate is simultaneously a sensor that forms a probe

electromagnetic field in the environment under control. Due to the sensor having an immediate contact with the

environment under control, the sensor has got a maximum sensitivity.

It should be noted that a moisture

measurement sensor of such a construction is definitely much more resistant to impacts from front surface in

comparison to the sensors which have got their sensitive element covered by the fragile ceramic

plate.

To achieve the effective control of the mixing process it is recommended to display the

information to the computer, meanwhile the operator can monitor the process of concrete preparation in

dynamics. It allows reducing the concrete mixing cycle and unloading the mixer not after the specified time

runs out, but when the required homogeneity of the mixture is achieved.

The moisture measurement sensor

is available in a version for mounting on the hopper wall or on the panel board located above the conveyor

belt. The sensor may also be installed in a hole drilled in the bottom of the concrete-mixing machine or on

its wall. The package includes all necessary mounting hardware.

There is a thermocouple installed inside the sensor to control the process temperature.

The sensor housing as well as its external elements are made of stainless steel (AISI 321 and AISI 420

correspondingly). That is why they are resistant to abrasion.

| Moisture Measurement range | 0 ... 100 % |

| Limits of permissible absolute error of the measurements results of the mass fraction of water |

ΔW= 0,02 +0,025·W |

| Temperature measurement range | -40 ... +150 °C |

| Range of working temperatures | -20 ... +180 °C |

| Operation mode continous | Continuous operation |

| Voltage supply - Rated / - Allowable | 24 (18 ... 36) VDC |

| Consumption current, not more than | 200 mA |

| Warm-up time at start-up | 90 min |

| Output | RS 485 Modbus RTU, 4-20 mA [RS485: max. cable length 1,000 m; 4-20 mA: max. cable length 100 m (max. cable length to SPS unit)] |

| Dimension of the sensor | 164 х 120 mm |

| Overall dimension of the electric unit | 255 х 170 x 60 mm |

| Protection class (sensor) | IP 67 |

| Protection class (electric unit) | IP 54 |

| Electric unit mass | 3.5 kg |

| Moisture W [%] | Absolute error ΔW [%] |

| 0 ... 10 | 0,5 |

| 10 ... 20 | 1.0 |

| 20 ... 50 | 2.5 |

| 50 ... 100 | 5.0 |

Notes:

For dry and high-flow concrete-mixing

machines, water content does not exceed 14%; therefore maximum moisture value of 20% (ratio of water

weight to the total weight of the concrete mix) is set in the calibration characteristics for moisture

measurement meters installed in concrete-mixing machines.

Calculation by the following

mathematical equations (formulae) gives the following values of the absolute error Δ: Moisture range W

Acceptable absolute error limits Δ up to 10%, 10…20%, 20…50%, 50…100%, 0.5%, 1%, 2.5%, 5%.

Using

the supplied software by the method described in the operating manual, the user can adjust moisture

meter calibration data for the enhancement of moisture measurement temperature range.

The

required cable length between the moisture measurement sensor and the electronic unit is agreed when

ordering

PCE-MWM 220 VHF-Band Moisture Measurement Sensor Liquid Materials (pipe installation)

The frequent and important peculiarity which should be considered in any kind of industry and production is

that the material used in the production process has got a certain amount of moisture in it. It goes not only

about bulk materials (such as sand, rubble, ore, gravel etc), but about liquids as well (oil, fuel oil,

coal-water slurry fuel (CWSF), petroleum etc). Though all the versions of the moisture meter have got similar

structure each versions performs its own function.

The device consists of an electronic unit and a

sensor.

The flanges of the sensor which is made as a pipe section are made of stainless steel. A probe

which is inside the pipe is made as a flat-topped stick of stainless steel of the same grade. Because of the

probe being equipped with a thermocouple, it is possible to carry out temperature control. The length of the

pipe section with the flanges is 400 mm. The moisture meter is available in several versions with different

nominal bore: DN 50, DN 80 and DN 125 mm, and different allowable pressure: PN 1.6 (16 atm); РN 2.5 (25 atm);

РN 4.0 (40 atm); РN 6.3 (63 atm) and РN 10.0 (100 atm).

All the parameters can be adjusted depending

on the needs of the customer. Due to the material the moisture meter is made of the device is resistant to

corrosion, abrasive materials, mechanical stress. It also allow suing the sensor for measurements at very high

temperatures (145° C). On request it is also possible to provide the device operating at the temperatures of

350° C. The temperatures range can be even higher, due to the use of ceramic plates and high-temperature

alloys.

The electronic unit can have an explosion-proof enclosure as well as the general purpose

version.

Moisture meters for liquid materials are used in boiler installations, water-dosing and diesel oil emulsion

dispersion systems. The scope of supply can include the control cabinet to operate the valves regulating water

feed. The moisture meter for liquid materials has a processing unit with RS232/RS485 interfaces (can be easily

included into ACS-automatic control systems); and its supply package includes software suitable for Windows,

as well as the control cabinet to operate the valves regulating water feed.

Moisture meters for liquid

materials are used in boiler installations, water-dosing and diesel oil emulsion dispersion systems. The scope

of supply can include the control cabinet to operate the valves regulating water feed. The moisture meter for

liquid materials has a processing unit with RS232/RS485 interfaces (can be easily included into ACS-automatic

control systems); and its supply package includes software suitable for Windows, as well as the control

cabinet to operate the valves regulating water feed.

| Measurement range | 0 ... 100 % |

| Limits of permissible absolute error of the measurements results of the mass fraction of water | ΔW= 0,02 +0,025·W (seen Note 1) |

| Media temperature range (steam temperature) | -40 ... +345 °C (depending of the model) |

| Range of environmental working temperature | -20 ... +120 °C |

| Operation mode continous | Continuous operation |

| Measurement period | 1 s |

| Voltage supply - Rated / - Allowable | 24 (18 ... 36) VDC |

| Consumption current, not more than | 200 mA |

| Warm-up time at start-up | 90 min |

| Output | RS 485 Modbus RTU, 4-20 mA [RS485: max. cable length 1,000 m; 4-20 mA: max. cable length 100 m (max. cable length to SPS unit)] |

| Pressure | PN 6 ... PN 160 (... 160 bar ≙ 16 MPa) |

| Dimension of the sensor | DN 50, DN 80, DN 100 or DN 125 (depending on the variant) / length allways 400 mm |

| Overall dimension of the electric unit | 255 х 170 x 60 mm |

| Protection class (sensor) | IP67 |

| Protection class (electric unit) | IP66 (explosion-proof) |

| mass Sensor | 9 ... x kg (depending on wall thickness, pressure range |

| Electric unit | 2 kg |

| Electric unit (explosion-proof) | 8 kg |

| Moisture W [%] | Absolute error ΔW [%] |

| 0 ... 0,3 | 0,3 |

| 0,3 ... 3 | 0,1 |

| 3 ... 7 | 0,2 |

| 7 ... 10 | 0,3 |

| 10 ... 20 | 0,5 |

| 20 ... 40 | 1,0 |

| 40 ... 100 | 2,5 |

PCE-MWM 230 VHF-Band Moisture Measurement Sensor Crushed Stone, Gravel, Ore (conveyor)

A vast majority of materials contain moisture, which can be sometimes not to detect visually. To avoid

mistakes in the production and to improve the quality it is necessary to take into consideration how much

moisture any of the materials under control contains.

When it goes about liquids and bulk materials the

right choice is the dielectric moisture meter PCE-MWM 230. Generally speaking there are a few models of the

moisture meter which are meant for measuring of some particular materials and that is why that device a very

wide application (mining and petrochemical industry, production of building materials, agriculture). There is

no need in calibration in advance, as the principle of the device is based on the direct method of

permittivity measurement. The measurements can be carried out not only for homogeneous materials but also for

materials with fractions (crushed stone, gravel, ore etc). The device is non-nuclear, which is a big

advantage.

For the enterprises dealing with the carbonated concrete rubble the device is irreplaceable.

The level of moisture can reach the mark of 8%, almost equal to sand. The general description of the moisture

meter structure is the following: an electronic unit and a probe-sensor made of stainless steel.

As it

has been mentioned above the moisture meter is capable of measuring moisture in many materials, both

homogeneous and heterogeneous, petrol and fuel, large-granulated bulk materials, agricultural products and

crops etc. It is possible due the use of the very high frequency waves. This wavelength range makes the

moisture meter a VHF band radio device. Moisture meter covers the whole volume of the material (even when

there are big fractions) averaging the result of the measurements

It looks pretty simple-constructed, having a probe and two pins. The device can be mounted even on the wall of

the reservoir or tank due to the cylindrical housing with G1 1/2" thread.

It can also be installed on

the tube in the hopper as the coupling with thread G1" is directly at the top of the housing. As a result the

probe will be over the hopper outlet.

The device is resistant to corrosion (stainless steel and

dielectric materials) and can operate in the conditions deviating from the norm, for example, at temperatures

of 145°C. The moisture meter probe can be mounted on the walls in the hoppers, in pipelines or on trays in

conveyors. Due to pluggable design this version of the moisture meter can also be used for soil moisture

control.

| Measurement range | 0 ... 100% |

| Limits of permissible absolute error of the measurements results of the mass fraction of water | ΔW= 0,02 +0,025·W (Seen Note 1) |

| Range of working temperatures | 0 ... +90 °C (industrial version) 0 ... +155 °C (extended temperature range) 0 ... +250 °C (drying kilns) |

| Operation mode continous | Continuous operation |

| Measurement period | 0,3 ... 1,5 s |

| Voltage supply - Rated / - Allowable | 24 (18 ... 36) VDC |

| Consumption current, not more than | 200 mA |

| Input power | < 0,1 W |

| Warm-up time at start-up | 30 min |

| Output | RS 485 Modbus RTU, 4-20 mA [RS485: max. cable length 1,000 m; 4-20 mA: max. cable length 100 m (max. cable length to SPS unit)] |

| Dimension of the sensor, length | L 500 ... 1000 mm, Ø 15 ... 30 mm (depending on the variant) |

| Protection class | IP 54 |

| Mass | 5 kg |

| Moisture W [%] | Absolute error ΔW [%] |

| 0 ... 6 | 0,3 |

| 6 ... 8 | 0.4 |

| 8 ... 10 | 0.5 |

| 10 ... 20 | 1.0 |

| 20 ... 50 | 2.5 |

| 50 ... 100 | 5.0 |

The first version of the device is designed for installation on concrete product plant dispensers to control

the moisture carbonate rubble, granite gravel and sand. Using of the moisture meter is the most effective when

it is operated as a part of the automated concrete mixing plant system. According to the results of sand,

crushed stone and gravel moisture measurements, the ACS automatically adjusts the dose weight of inert

components and water. This significantly improves the quality of mixtures and reduces the loss of time on

their correction.

The second version of the moisture meter PCE-MWM 230 is designed for measuring of

permittivity and water content in the diesel oil emulsion. This version of the moisture meter is made as a

tube with flanges of DN 50 mm cross section.

PCE-MWM 240 VHF-Band Moisture Measurement Sensor for Bulk Material

A bulk moisture meter is an irreplaceable device when it is necessary to measure the content of moisture in

various materials, either in mining, petrochemical industry, or agriculture as well as in the production of

the building materials. A non-nuclear device, which means that the moisture meter does not contain any

radioactive material, is safe to be used and frees the customer from the need to ensure radiation safety, as

well as from expenses for nuclear devices disposal. Moreover, there is no need to obtain a license for

handling devices and machines generating ionizing radiation.

The advantage and strength of the devices

construction is that it is based on the VHF band waves. To be able to measure non-uniform materials the

wavelength must exceed the size of the granules of the tested material, only in that case it won’t get weaker

and scatter on inhomogeneity. The granules can be even greater than 5 cm in diameter and that is why such

materials as sand, gravel, crushed stone, sawdust, grains, flour, seeds, wood and rubber chips, ore, etc. are

all included into the list of possible materials for measurements taken with the help of the moisture meter.

It allows to get very accurate results by averaging them over the whole volume of the materials even with

non-uniform materials.

As in all our moisture meters the structure of the PCE-MWM 240 is rather

simple: electronic unit and sensor (includes a probe in shape of stainless steel stick with a diameter of

14-30 mm). The sensor of the device is very strong and resistant to negative influences such as mechanical

stress from abrasive materials and is also mechanically stable and leak-proof. The probe is even suitable for

operation under very high temperatures of up to 200 °C due to the stainless steel and ceramic seals which are

used during its production.

Depending on the material flow there are two versions of the moisture meters (both are designed for hoppers

and conveyors).

Version 1 (PCE-MWM 240-A): The sensor probe has a U-shape bracket which is mounted on

the wall of the hopper via couplings. Moisture meter is meant for moisture measurement of the bulk materials

(crushed stone, silicate mass, clay, sand, sawdust, etc) in the bunkers, silos, batchers, conveyer belt, and

mixers used in the silicate brick production, as well as screw conveyors.

When the sensor with the

U-shape probe is set up on the conveyor belt, the flow of the bulk material is formed from the sides by the

guiding plates. Viewed from above the flow of the material is limited by the plate that stabilizes the density

of the material in the measured area and guarantees high measurement accuracy.

Version 2 (PCE-MWM

240-B): The sensor probe has a straight rod shape with the ends fixed by special couplings on the opposite

walls of the hopper. The sensor allows control of large volumes of material ensuring accurate data about the

of moisture content in the material.

The moisture meter is meant for measuring moisture in the bulk materials (sand, crushed stone, silicone mass,

clay etc) in bunkers, silos, and batchers. A special feature of this model is the large probe length (up to

1.2 m), and the volume measured up to 1 cubic meter. The differences in moisture of separate local areas and

also material sticking to the walls of the bunker do not influence the quality of measurement

results.

Moisture meter installation at the feed bin outlet allows to evaluation of the moisture of the

material directly before the dosing. This solution allows the total dose of water in the inert volume put into

the concrete mixer to be determined.

The sensor in the shape of a straight rod is simple and very

resistant to any mechanical impacts, hits and vibration. Flange mounting of the probe to the bunker ensures

its secure fit and allows you to quickly remove and install the sensor in minutes.

If the bulk product

is loaded on the conveyor from above then the collecting duct with a direct probe should be mounted in the

loading area above the belt. The probe is mounted in couplings on the duct walls as it shown in the figures

below.

The moisture meter is meant for moisture control in wood chips, sawdust, sand, clay and other similar

materials. The probe of the sensor is a pin with the length up to 0.6 m, made of stainless steel bar

12X18H10T, probe diameter – 14 mm. The sensor of this moisture meter and be fixed on the walls of the bunker,

as well as above the conveyor belt.

The recommended application – to set up in the places of material

unloading on the conveyer. In the loading area a collecting box is installed above the belt. The probe is

fixed in the coupling on the walls of the box.

The measured material should cover the probe completely;

the thickness of the material layer above the probe must around 20 cm. The required height of the pile of the

material which is filled can be achieved by the conveyer speed regulation, as well as by setting up an

additional flap in the box outlet, partly overlapping the flow. As the probe is made as a threaded rod and its

length can be changed within a wide range (from 20 cm to 50 and more cm), the level of the material can also

be regulated by choosing the right width of the duct.

A few peculiarities helped to improve the

production of pellets where the sawdust control became possible. In the picture it can be seen that the

sawdust can also be controlled in the screw when the moisture meter is in it.

As mentioned above the

device can be used in hoppers and conveyors. And the probe can be mounted on the walls in special steel plug

holders. It is easy to both, insert for installation and to remove it through the holes in holders. The

mounting is made with the help of coupling holders with metal base directly on the hopper wall or metal

shield. The moisture meter design allows to simply perform mounting and dismounting of the sensor during

operation. The coupling holders are welded directly to the hopper wall or are fixed by welding on a separate

shield, which is installed and fastened to the hopper wall. This solution eliminates the need for precise

adjustment of the couplings while mounting them to the hopper wall.

The probes can be different in size

and vary from 20 cm to 1.5 m. The long probe provides averaging of measurement results over the entire volume.

Moisture differences in local areas do not lead to errors in the moisture measurement.

The moisture

meter is suitable for installation on concrete product plant dispensers to control the moisture of carbonate

rubble, granite gravel and sand. Using of the moisture meter is the most effective when it is operated as a

part of the automated concrete mixing plant system. According to the results of sand, crushed stone and gravel

moisture measurements, the ACS automatically adjusts the dose weight of inert components and water. This

significantly improves the quality of mixtures and reduces the loss of time on their correction.

| Measurement range | 0 ... 100 % |

| Limits of permissible absolute error of the measurements results of the mass fraction of water | ΔW= 0.02 +0,025·W (seen Note 1) |

| Range of working temperatures | -20 ... +145 °C |

| Operation mode continous | Continuous operation |

| Measurement period | 1 s |

| Voltage supply - Rated / - Allowable | 24 (18 ... 36) VDC |

| Consumption current, not more than | 200 mA |

| Input power | 0,1 W |

| Warm-up time at start-up | 30 min |

| Output | RS 485 Modbus RTU, 4-20 mA [RS485: max. cable length 1,000 m; 4-20 mA: max. cable length 100 m (max. cable length to SPS unit)] |

| Dimension | L 500 ... 1500 mm, Ø 15 ... 30 mm |

| Overall dimension of the electric unit | 255 х 170 x 60 mm |

| Protection class (sensor) | IP 65 |

| Protection class (electric unit) | IP 54 |

| Mass | 3,5 kg |

PCE-MWM 300P Microwave Moisture Measurement Sensor (Pellets, Wood Chips)

Online wood moisture measurement during the industrial production process of wooden composite panels (i.e. PB,

MDF, OSB) or pellets and wood chips is of fundamental importance in order to ensure that processes run as

efficiently as possible, energy consumption is kept low and raw material losses are minimized.

In

comparison to all conventionally employed moisture sensors the use of a microwave moisture measurement system

provides much higher consistency and product quality levels while reducing operating and maintenance costs at

the same time. When the inprocess measurement instrument is connected to a controller or a process control

system the operator has the ability to react to measurement results in real time. - Fast, accurate and

reliabler industrial processes are set up by using microwave moisture measurement.

This, in turn,

results in less downtime during pressing or drying processes and the loss of material is reduced. The

investment recovery period for the moisture measurement sensors is thus very small, usually it only takes a

few weeks for it to pay off completely.

When it comes to online moisture measurement the microwave sensor is a valuable tool in many stages of the

production process: in refining of wood materials, in resin treatment, during pressing, dewatering and final

drying. The moisture sensor (moisture measurement instrument) provides particularly good results for the

moisture measurement of pellets, sawdust and wood chips, pulps which are homogeneously mixed and pre-dried.

This kind of moisture measurement sensor can be used for a wide range of materials.

Measurable

materials:pellets, bulk materials, granules, panels, wood panels, wooden panels, MDF, wood flour, sawdust,

fiber material, wood fiber, pulp, textile, textiles, wool, yarn, powdery material, wood chips, oxides,

hydroxides, stone dust, asbestos, fiberglass, fabric chips, soot, cinder, dyes, tiles, calcium carbonate,

tiles, ceramics, wood flour, powder, sawdust.

Technical specifications:

| Moisture measurement range | 0 ... 100 % |

| Max. permissible absolute error of humidity measurement | ±0.2 % |

| Reproducibility | ±0,01 % |

| Working temperature range | 0 ... +60 °C / +140 °F |

| Working mode | Continuous operation |

| Power supply | 24 V DC |

| Input power | <9 W |

| Radiation output of the microwave sensor | <0.1 W |

| Warm-up time at start-up | 90 min |

| Outputs | Ethernet (100 Mbps), 4-20 mA |

| Input | 2 x digital 24V DC |

| Dimensionen (Sensorkopf / Gehäuse) | 65 x 150 / 270 x 120 mm |

| Protection Class | IP 66 |

| Weight | 5 kg / ~11.3 lbs |

The increased accuracy of online / inprocess moisture measurement and humidity control guarantees a more

uniform final product (i.e. MDF, OSB). Additionally, since the drying process of these materials is very

costly, controlling this part of the process efficiently, provides the greatest cost benefits. Drying

temperatures which are set too aggressively are not only a waste of energy but they also lead to unwanted

deterioration in fiber quality, especially on wooden products.

Here are some of the possible

application areas for the inprocess microwave moisture measurement sensors in manufacture and processing:

fiberboard (PB, MDF, OSB), sawdust, woodchips (for combustion), wood slats, wood panels, and wood pellets.

They are even employed when wood pellets are burned in industrial or combustion plants in order to control

the pellet feed rate.

PCE-MWM 400L Microwave Moisture Measurement Sensor (Food, Pasty Media, Powders)

Food moisture measurement is an important part of food manufacturing processes. These processes are

characterised by the conversion of raw and auxiliary materials into powdered food products and base materials

with a low moisture content in the food industry.

This process leads to increased preservation

properties by reducing the harmful growth of bacteria and thus increasing the medium- and long term durability

of goods. The food industry operates under the requirement that foods must be safe for human consumption. The

food microwave moisture sensor helps food producers to minimize the risk of food contamination.

Based

on these food industry regulations, the real-time / inprocess moisture measurement is essential. Risk of

contamination originating from raw materials, packaging materials or the manufacturing process itself must be

eliminated - very, very important in food processing.

Inprocess microwave moisture sensors are an ideal

solution for continuous moisture measurement in the manufacture of food powders like dry milk, egg powder and

baby formula powder. The measurements deliver the necessary data for food process control.

The encoder housing is made of a special anodized aluminum alloy (*). The real-time measurement as well as the

control of the drying (spray-drying) process results in higher productivity and food manufacturing process

safety. The processability of raw materials increases and energy consumption decreases. Due to the fact that

the moisture measurement is independent of the coloration/dye and the particle size of the material, the

measurement accuracy is higher and the need for re-calibration lower, particularly in comparison with NIR

measurement methods.

Measurable materials: food, pet food, dog food, feed, animal feed, cat feed,

paste, yoghurt, milk powder, biomass, powdery material, calcium carbonate, pasty media, dough, flour powder,

chocolate, mass, cacao mass, noodles, pasta, pudding powder, honey, meat, salt, dried food, fermented food,

snack food and sugar.

| Moisture measurement range | 0 ... 100 % |

| Max. permissible absolute error of moisture measurement | ±0.2 % |

| Reproducibility | ±0.01 % |

| Working temperature range | 0 ... +60 °C |

| Working mode | Continuous measurement |

| Power supply | 24V DC |

| Input power | <9 W |

| Radiation output of the microwave sensor | <0.1 W |

| Warm-up time at start-up | 90 min |

| Dimensiones (sensor): | L 500 ... 1500 mm, Ø 15 ... 30 mm |

| Outputs | Ethernet (100 Mbps), 4-20 mA |

| Inputs | 2 x digital 24V DC |

| Housing material | Anodized aluminum |

| Protection Class | IP66 |

| Weight | 5 kg / ~11.3 lbs |

(*) Maintenance is one of the main criterias in food manufacturing. That is why there are sharp regulations given by country depending authorities. In the US, the Food and Drug Administration (FDA) is responsible for that. Why should these regulations are be made? When the food manufacturing process is not sanitary, it can cause dramatic health problems by having contaminated surfaces. Food cause illnesses and diseases are more than 50 millions per year. Therefore all materials used in food manufacturing should be chosen carefully, but in any case made of anodised aluminium or stainless steel.

PCE-A-344W Microwave Sludge Consistency Sensor (Waste Water / Mud Consistency)

These sludge consistency measurement instruments (detection of dissolved substances, suspended solids in

wastewater) are based on the microwave measuring method. The instruments sensors are majorly deployed in

municipal sewage treatment plants as well as for consistency measurements in industrial plants. The sensor can

measure the exact amount of solids (in total or as active sludge) in any wastewater.

Through the

installation of microwave sensors plants experience up to 20% of savings in the use of flocculants. This

translates into substantial cost savings for the plant operators. The payback period for the initial

investment is thus reduced to a few weeks or months (depending on the size of the wastewater treatment

plant.)

Advantages of the use of inprocess PCE-A 344W sensor:

- Fulfillment of technical

requirements and environmental standards

- Optimization of the automation process

- Reduction in the use

of polymers

- Reduced energy consumption

- Reduction in the number of laboratory tests

- Optimization

of flocculant use (optimal dosage can be reliably determined)

| Concentration range / Measurement range | 0 ... 8 % |

| Reproducibility | ±0.02 % (absolut) |

| Measuring interval | 1 s |

| Process temperature | +5 ... +50 °C / +41….+122 °F |

| Measurement results | Continuous |

| Power supply | 24 V DC |

| Input power | 0.2A |

| Standard signal output | 4 ... 20 mA |

| Conductivity limit | 10 mS / cm |

| Protection class | IP 65 |

| Weight | Approx. 26.5 lbs / 12 kg |

The inprocess microwave consistency sensor was originally developed for the determination of pulp and

wastewater fiber consistency in the paper industry. The microwave measurement / operating principle of the

sensor allows for the determination of consistencies without calibration. In contrast to optical methods,

this kind of measurement instruments does not deliver erroneous results. The system requires very little

maintenance.

The microwave measurement sensor is inserted into a pipe and the current sludge

consistency of the wastewater can be read on the display. Additionally, the sensor can be integrated into an

automated control system like DCS. PCE Instruments offers remote control and maintenance for all sensors.

The sludge consistency instruments offer precise measurements with the sensor operating independently of

flow rate or sludge structure. There is no need for further maintenance after installation.

Application

Dryers

In the dryers a combination of two moisture measuring sensors is usually

used. By means of the input moisture of the respective material (before the dryer) either the incoming amount

of material can be regulated by means of the entry speed or with the same entry amount the drying power in the

system can be regulated. Nevertheless, both versions need the final dry content, or final moisture of the

material at the output of the dryer in order to close the loop.

For materials, like bulk materials,

which show a relatively “stable” input moisture (only small seasonal fluctuations, such as summer to winter),

the moisture measurement with the sensor before the dryer may be not necessary. In that case, the moisture

meter is mostly used for adjusting the drying capacity at the desired final moisture content

Screw conveyors

In a screw conveyor, the moisture measurement is carried out

directly in the mass flow of the material. Here a contacting measurement of moisture is appropriate, because

the material surrounds the sensor completely and there is always high and even compression. That makes the

inprocess moisture measurement with high accuracy and also higher reproducibility of the measurement results

possible.

If the mass flow must not be impaired in any way, PCE applies contactless moisture meters. In

both cases there is no need for bypass bringing of the material at the inconsistent flow rate or low material

flow.

Conveyors

For inprocess moisture measurement on conveyor belts PCE Instruments also

offers contact or contactless moisture meters. Depending on the material to be measured and the possible

installation areas, the optimal model can be chosen. If you can provide a sufficient and uniform coverage of

the moisture meter with the material at the input (e.g. case funnel), then a much lower cost contact sensor is

the best choice. The usage of additional carriage-like constructions (which is needed for the moisture sensors

of the other producers) is waived for the PCE measuring instruments.

Also for mixers, case funnels, containers, silos, bunkers, etc. PCE offers appropriate solutions for inprocess

moisture measurement. Bulk, material with parts of the size up to 10 cm is reproducibly measurable.

Furthermore pipe fittings with the integrated sensors for moisture measurement in suspensions, wet mixtures

and even for detecting the condensate amounts in saturated steam are available.

All sensors are either possible to use directly in explosion hazardous areas or available in

explosion-proof version.

Adjustment - Calibration

Each moisture meter is delivered to the customer in a preset condition (factory adjustment). For that, for

familiar materials, such as wooden pellets, coffee beans, sand (bulk material), oil, concrete….the calibration

curves (material characteristics) for the moisture meter can be taken from the PCE database. When it goes

about materials which have not been registered yet, mixtures or substances with big density fluctuations, a

small sample amount is sent to one of the respective PCE branches in order to carry out some tests. After this

material testing it quickly becomes clear, what type of sensor is suitable for this specific moisture

measurement.

Then the mechanical installation of the moisture meter can follow on site directly at the

production plant. After the electrical connection a warm-up and onset phase takes place. When this phase is

complete, the adjustment process can be started. Depending on the production speed 10 -15 material samples can

be drawn (after passing the measuring point) and the corresponding electrical output signals (high frequency

signals) of the moisture meter are recorded (captured).

Based on the sample materials, the absolute moisture by means of the moisture detecting scales (provided by

PCE) is determined. There results of the moisture measurement by means of the moisture detecting scales are

correlated with the electrical output signals of the sensor. As a rule, it goes about linear relationships

which lead to a very good correlation. For some materials, as well as for some very inhomogeneous substances

and big density fluctuations it can happen that to improve a correlation a bigger number of the samples may be

necessary.

Likewise, because of the correlation results an adjustment of the algorithm stored in the

moisture meter can be required, because this algorithm presents mathematical relationship between the

measurement values of the absolute moisture measurement and the absolute moisture values of the sample

received with the help of the moisture determining scales. Due to the measuring principle and the

constructional design the sensors for absolute moisture measurement are not subject to any drift because of

aging or external factors. The maintenance is thus very low. All the products for moisture measurement

(absolute) are patented and CE certified.