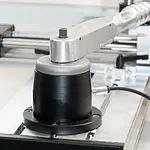

The torque wrench tester consists of a handheld measuring device and an external torque transducer. The torsion transducer is connected to the hand-held device via a 1.5 m / 4.9 ft long cable and thus enables installation in a test stand or direct assembly on a test bench.

The torque measuring device is delivered adjusted so that the control measurements can be started immediately. A calibration certificate is optionally available for the torque measuring device. This certificate is a target / actual comparison on a traceable reference standard and thus serves as proof of the measurement accuracy. The measurement uncertainty of the torque measuring device is only 0.5% of the measuring range. The torque measuring device is therefore used as a reference device for testing and adjusting static torque tools. A screw latch is essential for dynamic torques.

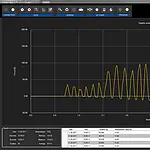

The torque transducer has a 1/2" square socket and can perform the torsion measurements in both directions of rotation. With a sampling rate of 1600 Hz, the torque meter reliably detects the first and the maximum torsional moment peak (PEAK). The release moment (" click ") is shown separately in the display and can be deleted either manually or automatically after a set time has elapsed. Thanks to freely adjustable alarm values, the torque measuring device can warn the tester of overload of the torque tool if it does not trigger itself. For a more detailed analysis of the torsional forces, the PC software included in the scope of delivery can be used.

Torque wrench is one of the perfect tools that help to carry out the tasks, such as screws and nuts tightening, as accurately as possible. It definitely wins in comparison with common wrenches and is especially recommended for application in the case of very sensitive materials which can be damaged when too much targeted stress occurs. With the torque wrench the user does not need to doubt anymore whether enough power has been applied and whether the construction with the screw is reliable enough, since it goes not about sensing and approximate evaluation, but about precise measurement. The range of application of the torque wrench is wide, including automotive industry, shipbuilding, various construction and repair tasks. Tightening is one of the essential quality parameters and application of the correct equipment allows reducing the risks of breakage and failure of the equipment and parts with the tightened screws to minimum.

Too tight is exactly as bad as not tight enough, since both may lead to serious problems, from elementary spoilage of the parts to very dangerous accidents occurring as the result of insufficient attachment of the important element in the machine, car, ship and similar.

As a rule, the level of tightening is determined and specified by the manufacturer, after numerous checks and tests, that is why this verified value should not be neglected. Torque wrench allows for compliance with the requirements of the developer or manufacturer, which is the top-priority, especially when it goes about repair and maintenance services.

Working with torque wrench requires attention and proper adjustment. With the help of the torque wrench tester, an operator can calibrate and adjust the tool for the particular task. Thus, not the simplest instruments can demonstrate the best performance not only in the hands of the professionals, but also inexperienced users. The most modern models are equipped with several functions, which may include even sound notification, which makes it possible to apply the torque wrench even under the most challenging conditions, for example, when the visibility is limited.

As any instrument, the torque wrench must be always calibrated and checked before being applied in service life. Torque wrench meter helps to keep the tool always in the best condition and check whether it is suitable for the task or another model with a different range should be selected. The units in which the force / the torque is measured are also important. Depending on the specifications, and the country of origin, the units may vary, which may lead to false measurements – torque wrench should be calibrated fitting to the equipment on which it will be applied.

Application of the torque wrench tester also helps to detect and avoid the residual torque after tightening the joint. This is usually the final stage, when the quality control and assessment takes place. The principle “the more the better” does not apply in this case and, for example, excessive tightening must be strictly avoided. Due to the application of the digital tools the measurements can be quickly made and transferred to the computer for evaluation. Thus, the operator’s task is significantly facilitated and there is no need to approximate evaluation of the force applied.

Digital torque wrench tester is an accurate instrument which quickly points to the errors and helps to eliminate them precisely. The tester may be applied frequently, which not only helps to keep the tool in a perfect condition, but also carry out regular quality monitoring which is one of the essential parameters in any production and service.

The torque measuring device is delivered adjusted so that the control measurements can be started immediately. A calibration certificate is optionally available for the torque measuring device. This certificate is a target / actual comparison on a traceable reference standard and thus serves as proof of the measurement accuracy. The measurement uncertainty of the torque measuring device is only 0.5% of the measuring range. The torque measuring device is therefore used as a reference device for testing and adjusting static torque tools. A screw latch is essential for dynamic torques.

The torque measuring device is delivered adjusted so that the control measurements can be started immediately. A calibration certificate is optionally available for the torque measuring device. This certificate is a target / actual comparison on a traceable reference standard and thus serves as proof of the measurement accuracy. The measurement uncertainty of the torque measuring device is only 0.5% of the measuring range. The torque measuring device is therefore used as a reference device for testing and adjusting static torque tools. A screw latch is essential for dynamic torques. Working with torque wrench requires attention and proper adjustment. With the help of the torque wrench tester, an operator can calibrate and adjust the tool for the particular task. Thus, not the simplest instruments can demonstrate the best performance not only in the hands of the professionals, but also inexperienced users. The most modern models are equipped with several functions, which may include even sound notification, which makes it possible to apply the torque wrench even under the most challenging conditions, for example, when the visibility is limited.

Working with torque wrench requires attention and proper adjustment. With the help of the torque wrench tester, an operator can calibrate and adjust the tool for the particular task. Thus, not the simplest instruments can demonstrate the best performance not only in the hands of the professionals, but also inexperienced users. The most modern models are equipped with several functions, which may include even sound notification, which makes it possible to apply the torque wrench even under the most challenging conditions, for example, when the visibility is limited.