The hardness tester is used wherever a fast hardness test has to be carried out. It is possible with the hardness tester to determine the surface hardness of many metals. The hardness tester is particularly suitable for quality or material inspection. The measured values can be stored in the internal memory and recalled later. Please note that the measured values can only be read from the hardness tester on the display and it does not offer any readout.

One-hand operation of the hardness tester allows for convenient use in different locations. Due to its construction, the hardness tester also offers the possibility to determine the surface hardness in bores or other depressions. The small design of the hardness tester contributes to the functionality as does the light OLED. The OLED from the hardness tester shows many functions so that the user directly recognizes which parameters are measured, which measuring direction is selected, and which hardness has been measured.

| Measurement method | According to Leeb |

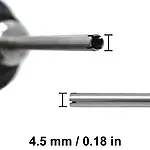

| Impactor | DL |

| Measuring range | HLD: 170 ... 960 HRC: 17.9 ... 69.5 HB: 19 ... 683 HV: 80 ... 1042 HS: 30.6 ... 102.6 HRA: 59.1 ... 88 HRB: 3.5 ... 101.7 |

| Measurement accuracy | HLD: ± 0.5% |

| Maximum hardness | 1042 HV |

| Striker | Type D |

| Display | 128 x 64 mm / 5 x 2.5 in OLED |

| Repeatability | HLD: ± 0.8% |

| Hardness max. | 1042 HV |

| Measurement units | HLD, HRC, HB, HV, HS, HRA, HRB |

| Display | 15 mm / 0.59 in |

| Material | Steel |

| Cast steel | |

| Alloy tool steel | |

| Stainless steel | |

| Cast iron | |

| Nodular cast iron parts | |

| Cast aluminum alloy | |

| Brass | |

| Bronze | |

| Tin bronze | |

| Measuring ranges on different material surfaces | |

| Material | |

| Steel | HRC: 17.9 ... 68.5 HRB: 59.6 ... 99.6 HRA: 59.1 ... 85.8 HB: 127 ... 651 HV: 83 ... 976 HS: 32.2 ... 99.5 |

| Tool steel | HRC: 17.9 ... 68.5 HRB: 59.6 ... 99.6 HRA: 59.1 ... 85.8 HB: 127 ... 651 HV: 83 ... 976 HS: 32.2 ... 99.5 |

| Stainless steel | HRB: 46.5 ... 101.7 HB: 85 ... 655 HV: 85 ... 802 |

| Cast iron | HB: 93 ... 334 |

| Brass | HRB: 13.5 ... 95.3 HB: 40 ... 173 |

| Bronze | HB: 60 ... 209 |

| Copper | HB: 45 ... 315 |

| Battery life | ca. 10 h |

| Power supply | Polymer Li-ion battery, 3.7V |

| Interface | USB 2.0 |

| Dimensions | 205 x 32 x 25 mm / 8 x 1.3 x 1 in |

| Weight | 650 g / 1.4 lbs |

| Display | 128 x 64 mm / 5 x 2.5 in OLED |

| Opearting conditions | -10 ... 50°C / 14 ... 122°F , <90% r.H. |

| Storage conditions | -30 ... 60°C / -22 ... 140°F, <90% r.H. |

1 x Hardness Tester PCE-2600N-ICA

1 x Impactor

1 x Calibration block

1 x Cleaning brush

1 x ISO calibration certificate

1 x Carrying case

1 x Operation manual

Calibration certificates are issued specifically for the customer and are excluded from the right of return.